The wire diameter density in the warp and weft directions is the same. The screen mesh of this weaving method has uniform mesh size, high filtration accuracy and stable structure. It is often used in occasions with high requirements for filtration accuracy.

Our Plain Vibrating Screen Mesh is designed for superior performance in various industrial applications, providing efficient screening and separation of materials. Constructed from high-quality wire mesh, it offers excellent durability and flexibility, making it suitable for both coarse and fine particle sizes.

The Introduction of Plain Vibrating Screen Mesh

As the main wearing part of the vibrating screen, the screen mesh is in direct contact with the material in the production process, which has an important impact on the production of the vibrating screen. The weaving method and structural form of plain vibrating screen mesh are diverse. Usually woven from metal wire, common materials include stainless steel, carbon steel, manganese steel, etc. It has a mesh structure with interlaced network cables, which is very stable has a certain strength and toughness and can withstand the impact and vibration of materials. This structure can evenly distribute materials on the screen mesh and ensure that particles have appropriate channels to pass through the sieve holes. Some sieves also have reinforcing ribs to enhance their overall deformation resistance. Widely used in industries such as food, mining, chemical, pharmaceutical, petroleum, metallurgy, machinery, protection, construction, handicrafts, etc. The aperture size of the mesh is uniform and can be customized according to different screening requirements.

1. Sturdy structure, stable surface, strong impact resistance, and good wear resistance.

2. The mesh size is uniform, the surface is flat, and the appearance is good.

3. High-temperature resistance, acid and alkali resistance, and corrosion resistance.

4. Various materials and specifications are available for selection, easy to process, and widely applicable.

Upgrade your screening operations with our Plain Vibrating Screen Mesh, engineered for high performance and reliability. Contact us today for more information or to request a quote tailored to your specific needs!

The Specifications of Plain Vibrating Screen Mesh

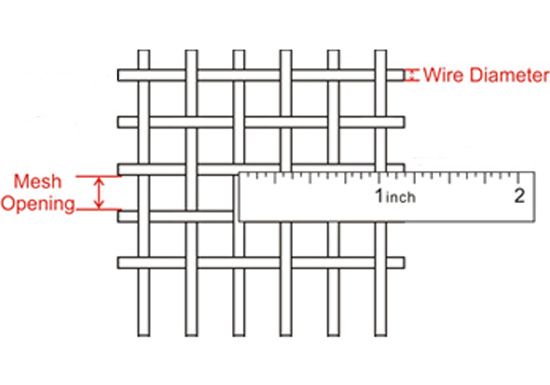

The following table shows the common specifications of plain vibrating screen mesh:

| Size | 1219.2*1892.3mm1000*2000mm |

| Wire diameter | 1.6m-12.0mm |

| Mesh opening | 3.0m-70.0mm |

| Material | Mild steel/Low carbon steel carbon iron wire65Mn steel wire galvanized steel wire stainless steel wire. |

| Type of edge | cut edge plain hooks hook with metal |

| Materials and specifications can be made according to customer-detailed requirements. Click here for customization details. | |

Can't find what you were looking for?

We can customize the product for you, determine the wire diameter, aperture, length and width, color, welcome to contact

● Enhanced screening efficiency for improved material separation

● Long-lasting performance, reducing maintenance costs

● Flexible design options to suit diverse operational needs

● Easy to clean and maintain, ensuring consistent performance

Plain weave mesh is a common type of mesh and the most basic weaving method. It is formed by interweaving longitude and latitude lines, where the warp and weft lines intersect with each other vertically, and each warp and weft line intersects with each other, forming a simple and regular square mesh plain weave pattern. Due to its numerous interweaving points, this weaving method makes the mesh structure more stable and the mesh surface flat. It can screen and filter granular, powdery and other materials, accurately separating substances of different particle sizes.

The intermediate pressure bonded woven screen is a special type of woven screen. During the weaving process, the intermediate crimping method is used to create a wavy shape, which is more stable than some ordinary woven mesh structures. From the appearance, this waveform structure makes the surface of the screen mesh not as flat as a plain weave screen mesh, but rather has a high and low undulating shape. During the weaving process, the mesh wire forms wavy patterns through special weaving techniques, which increases the effective screening area of the screen mesh. At the same time, it can withstand certain tension and pressure, which can better resist the impact and friction of materials during screening operations, reducing the deformation or damage of the screen mesh.

This type of screen adopts locking technology during the weaving process, which tightly fixes the intersection of the warp and weft lines of the screen, and each group of intersecting metal lines has protrusions or joints. This tight fixing method makes the structure of the screen very stable, able to withstand high pressure and tension, effectively preventing the screen from loosening and deforming during use. The lock press woven screen has uniform mesh holes, precise screening, high wear resistance, and long service life. Because it can accurately screen particles that meet the size requirements, even if they are subjected to material impact and friction for a long time, it can still maintain good screening performance, thereby ensuring the efficient and stable screening of materials.

All the ripples of the flat top woven screen mesh are bent in one direction, and the mesh surface is relatively flat without obvious undulations in appearance. During weaving, the interweaving of warp and weft lines forms a uniform mesh surface, which ensures the stability of the screen mesh during the screening process. Its sieve size and shape are relatively regular, and the aperture size and screening accuracy of the sieve can be adjusted by controlling parameters such as the thickness and density of the latitude and longitude lines to meet different usage needs. The initial purpose of developing a flat top screen was to provide a smooth surface for material flow or to serve as a support screen for finer mesh sizes. It is usually used for coarse mineral screening, and in addition, it is widely used in the construction industry.

Plain vibrating screen mesh is widely used in industries such as mining, chemical, pharmaceutical, petroleum, metallurgy, machinery, protection, construction, and technology.

● In mining: It can efficiently screen ores. The size of the extracted ore varies. By using a plain vibrating screen mesh, the ore can be divided into different grades according to the predetermined particle size, which facilitates the subsequent beneficiation process and improves the processing efficiency of the ore.

● In the field of building materials production: Such as sand and stone screening. It uses vibration to move sand and stones on the sieve, removing oversized or undersized particles that do not meet building standards, making the grading of sand and stones more reasonable, ensuring the quality stability of building materials such as concrete, and contributing to the safety and durability of construction projects.

● In the chemical industry: Screening of chemical raw materials is crucial. It can separate raw material particles of different sizes, provide uniformly sized raw materials for chemical reactions, and timely screen out impurities to ensure the purity and quality of chemical products.

● In food processing: It can be used for grain screening. By vibrating the grains to roll on the sieve, the crushed grains, impurities, and other particles that do not meet the size requirements are screened out, ensuring the quality of food raw materials and helping to produce high-quality food.